Fiber Laser Marking Machines

Fiber laser marking machines are used to mark all types of metals. These include gold, silver, copper, iron, aluminum, ABS, and PVC plastics.

Our fiber laser marking machines are known for their no-consumables, maintenance-free operation, energy-saving, and power efficiency.

UV Laser Marking Machines

UV laser marking machines are suitable for marking various materials, such as plastic, PVC, and glass. They can perform ultra-fine marking. They are ideal for ultra-fine marking applications like 3C electronics, food packaging, wires, lamps, leather, and pharmaceutical packaging materials. Due to their precise and high-quality marking effects, they are the first choice for people with stringent requirements for laser marking.

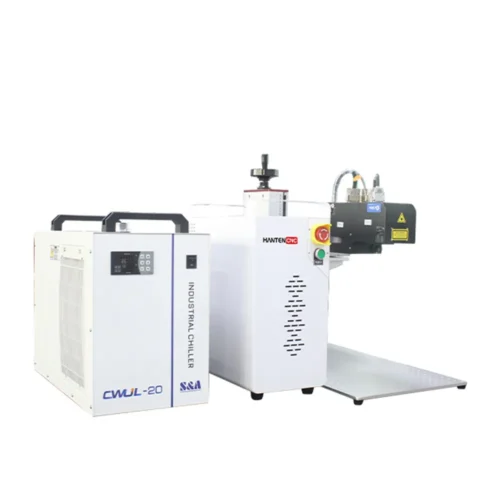

CO2 Laser Marking Machines

CO2 laser marking machines are suitable for marking a wide range of non-metallic materials and metal products. These include leather, wood, paper, ABS, PVC, epoxy resin, acrylic, glass, ceramics, rubber, bamboo, etc.

CO2 laser marking machines are widely used in plastics, textiles, leather, woodworking, handicrafts, electronic components, glasses, printing, pharmaceuticals, food packaging, automobile filters, and other non-metallic industries.

MOPA Laser Marking Machines

Due to the narrow width of the laser beam, the MOPA laser marking machine can achieve finer marking results. It is especially in applications requiring delicate patterns or high precision, such as metal surface color marking, mobile phone case back shells blackening, white plastic blackening, HDM black plastic whitening, thin plate de-layering, and anodized aluminum blackening.

MOPA laser markers can make fine, clear, durable, and permanent marks by removing surface layers or layers without damaging the underlying material.