Laser Welding Machines|Handheld Laser Welder Manufacturer

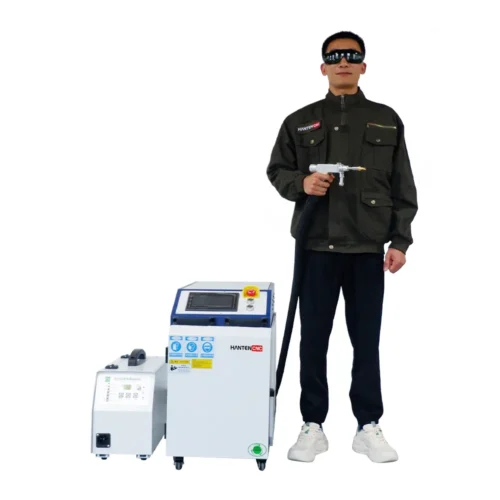

Laser welding is an ideal solution for welding metal materials like aluminum, stainless steel, copper, and various alloys. HANTENCNC’s laser welders, known for their cost-effectiveness, easy-to-operate, high-precision, high efficiency, and perfect welding effects, can meet various efficient and precise welding requirements.

As a professional laser welding machine manufacturer in China, HANTENCNC has 19 years of experience in designing and manufacturing handheld laser welders. HANTENCNC provides a wide range of laser welding machines with power ranges from 200W, 300W, 1000W, 1500W, 2000W, and 3000W.

Based on different mechanical designs, the collection of HANTENCNC’s laser welders includes handheld laser welders, desktop laser welders, gantry-type laser welding machines, and boom arm laser welding machines catering to diverse applications.

All of HANTENCNC’s laser welding machines are CE and FDA-certified. HANTENCNC offers a 2-year warranty for the laser source, a 1-year warranty for the whole machine, free sample testing, OEM customization, remote guidance, and lifelong after-sales support.