Professional Laser Machine Manufacturer | Laser Machine Experts

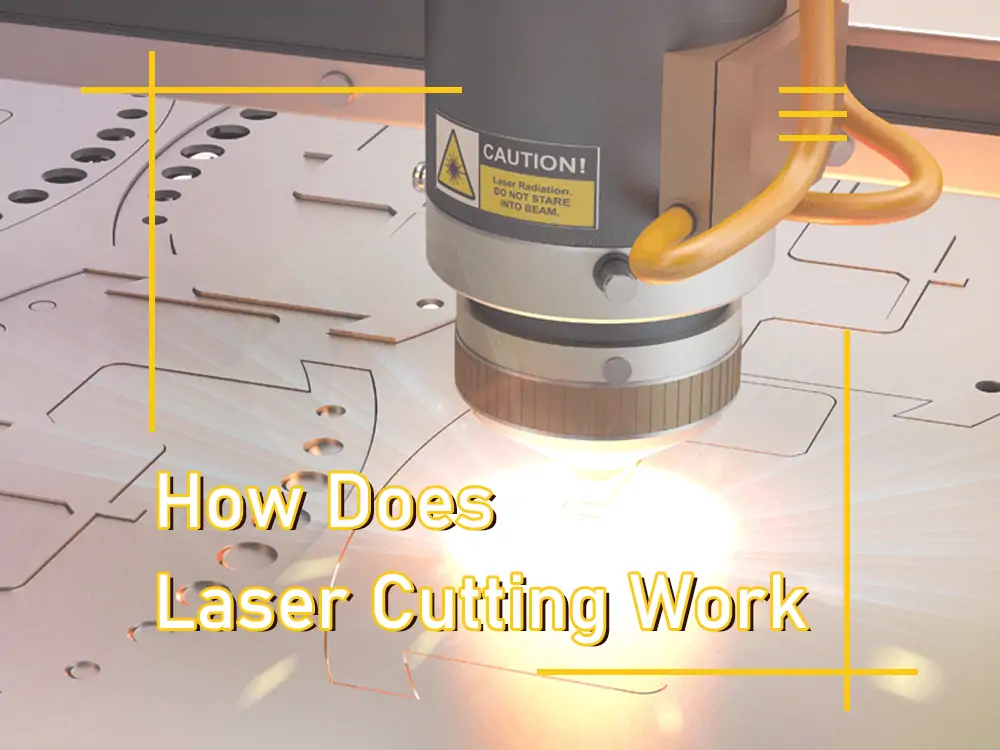

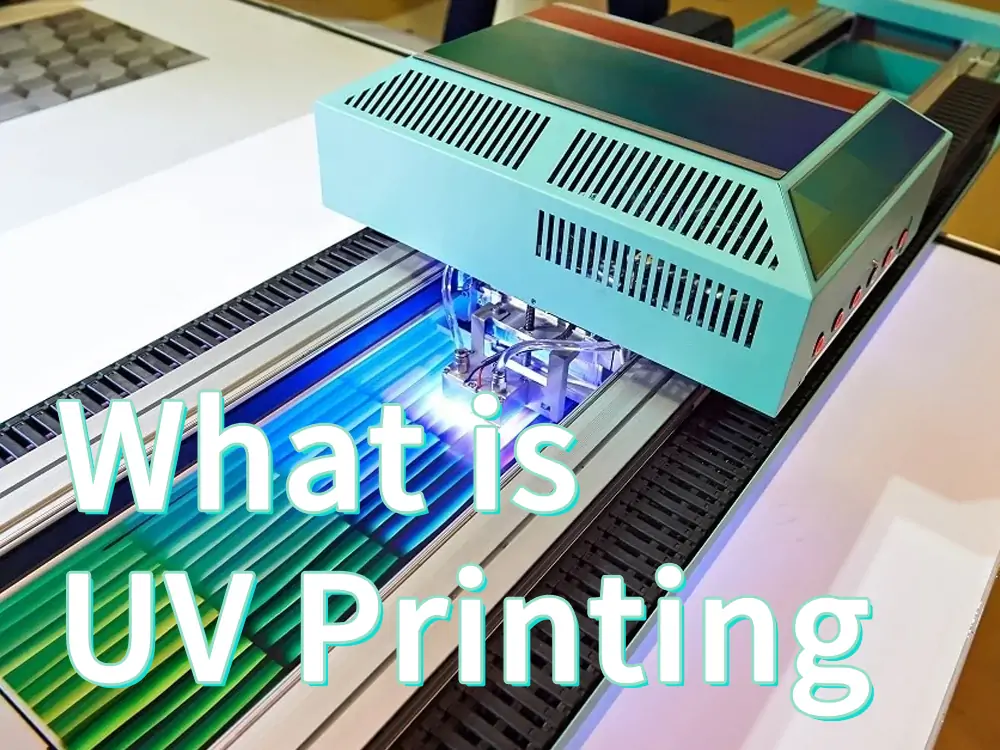

HANTENCNC is a professional laser machine manufacturer. We have over 19 years of expertise in designing and manufacturing laser machines. Our products include laser cleaning machines, welding machines, laser marking machines, laser cutting machines, and UV printers. Since HANTENCNC was established, our products have been exported to more than 100 countries. They are highly recommended and trusted by customers globally.

As a laser machine manufacturer and supplier, we own our factory so that we can offer a manufacturer-direct-sale price to our customers. All of our machines are CE and FDA-certified. HANTENCNC, your trustworthy laser machine partner!